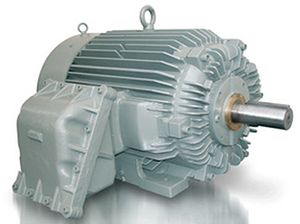

Here at Dietz, we’re proud to specialize in the supply and servicing of various types of hazardous location motors, designed to optimize workplace safety by containing explosions inside the motor itself. By keeping any flame source — such as sparks, flares, or combustions — contained, these motors help to prevent the spread of fire, as well as prevent further ignition and explosions outside the motor.

Also known as explosion proof motors, hazardous location motors play a critical role in protecting workers from potential injuries and even death.

The Importance of Hazardous Location Motors

In many industrial settings, workers operate equipment in environments that contain gas, vapor, dust, or other combustible elements. If an explosion was to occur within a machine’s motor in this type of setting, the initial explosion could ignite elements in the air, creating a much bigger explosion and putting workers’ lives at risk.

For this reason, explosion proof motors play an extremely important role in protecting employees and the environments in which they work by containing any possible explosions and also preventing larger ones from occurring. Hazardous location motors also protect company equipment and facilities as a whole, ensuring machinery is not damaged or ruined. Today, many government regulations and workers’ rights advocacy groups require that motors meet certain standards.

At Dietz, we have years of experience supplying hazardous location motors that meet the requirements set forth by the National Fire Protection Association (NFPA), and we are certified by several leading safety organizations, including UL, FM, and the Canadian Standards Association (CSA).

We remain committed to meeting both domestic and international standards, as set forth by UL, CSA, ATEX, and the International Electrotechnical Commission System for Certification to Standards Relating to Equipment for Use in Explosive Atmospheres (IECEx).

Applications and Classifications for Hazardous Location Motors

Hazardous location motors are essential for industries operating in environments where explosive gases, vapors, or dusts are present. These motors are specifically designed and classified to meet stringent safety standards, ensuring reliable operation in potentially dangerous conditions. Understanding the various classifications, such as Class I, Division 1 and 2, and their corresponding applications, is crucial for selecting the right motor to maintain safety and compliance in environments where the risk of explosion is a constant concern.

NEMA Classifications & Definitions

NEMA (National Electrical Manufacturers Association) classifications play a critical role in defining the safety and performance standards for motors used in hazardous locations. These classifications specify the level of protection that motor enclosures must provide against potentially explosive atmospheres, dust, and other environmental hazards. By categorizing enclosures according to their ability to withstand specific conditions, NEMA ensures that hazardous location motors operate safely and effectively in challenging environments. Understanding these classifications is essential for selecting the right motor for your application, ensuring compliance with safety regulations, and minimizing the risk of accidents in hazardous areas.

There are three main categories of classification:

- Division

- Class

- Group

Division: This category defines the likelihood of a hazardous substance being present in an area. There are two types of divisions:

- Division 1: A hazardous substance is likely to be present under normal operating conditions.

- Division 2: A hazardous substance is only likely to be present under abnormal conditions, such as equipment failures or other unusual circumstances.

Local safety authorities determine what constitutes normal and abnormal conditions. Therefore, the first step in classification is to consult with local authorities to identify whether a specific location falls under Division 1 or Division 2.

Class: This category defines the type of hazard present in the environment. There are three different classes:

- Class I: Involves chemical gases or vapors, such as gasoline or acetylene, which are present in the environment.

- Class II: Involves flammable dust, such as coke dust or grain dust, in the environment.

- Class III: Involves flammable lint or fibers, such as those found in textile production or sawdust, in the area.

Groups: This category identifies the specific chemical gas, vapor, or dust present in the environment. The term “group” refers to the classification of different atmospheric mixtures based on their hazardous characteristics.

- Groups A, B, C, and D: These groups consist of gases or vapors and are relevant only under the Class I category.

- Groups E, F, and G: These groups consist of dust and are relevant only under the Class II category.

Class I, Division 1 Motors

These electric motors are constructed to the requirements of U.L. Class I, Group C & D, Division 1. They are then modified to accept purge fittings on the motor and terminal box. In addition to the purge fittings the motor is also supplied with a Pepperl+Fuchs “Type X” purging system. This can be mounted on the motor, or wall mounted within 5 feet of the motor. The size of the motor is limited by the area to be purged.

The Pepperl+Fuchs “Type X” pressurization or purging system operates using a supply of compressed instrument air or inert gas. Its purpose is to regulate and monitor the pressure within the motor and terminal box, effectively removing and preventing the accumulation of flammable vapors or gases. In Class I areas, the system is designed to perform ten air exchanges and maintain a safe internal pressure of 0.25 inches inside the motor enclosure. The system also includes an Electrical Power Control Unit (EPCU), which monitors the operation of the system and controls the motor’s power. The EPCU ensures that all start-up requirements are met before allowing power to the motor. This process reduces the Hazardous (Classified) Area Rating within the motor and terminal box in accordance with NEC – NFPA 70, Article 500, NFPA 496, and ISA DS12.4.

Class I, Division 2 Motors

Class I, Division 2 motors are designed for use in environments where hazardous substances, such as flammable gases or vapors, are not typically present under normal operating conditions but may become present under abnormal circumstances, such as equipment failure or accidental release.

These motors are built to withstand and operate safely in such environments by minimizing the risk of ignition in the presence of flammable substances. Unlike Division 1 motors, which are designed for continuous exposure to hazardous conditions, Division 2 motors are constructed to ensure safety if a hazardous atmosphere briefly develops.

In these motors, components are typically enclosed to prevent sparks or high temperatures from igniting surrounding gases or vapors. They may also incorporate features like non-sparking parts or sealed enclosures to further reduce the risk of ignition. The design and construction of Class I, Division 2 motors adhere to stringent safety standards, ensuring that they meet regulatory requirements for use in potentially hazardous environments.

Overall, Class I, Division 2 motors are crucial for maintaining safety in environments where the presence of hazardous substances is infrequent but possible, ensuring that operations can continue without risking explosions or other dangerous incidents.

Class I, Groups A & B, Division 1 Purged Motors

What Are Purged Hazardous Location Motors and Why You Need Them

Purged hazardous location motors are specialized electric motors designed for use in environments where flammable gases, vapors, or dusts may be present, creating a risk of explosion. These motors are specifically constructed to meet the rigorous safety standards required for operation in Class I, Group A and B, Division 1 hazardous locations, where the presence of explosive atmospheres is a significant concern.

How Purged Motors Work

The base hazardous location motors are built to U.L. Class I, Group C & D, Division 1 standards and then modified to include purge fittings on both the motor and terminal box. This modification is what allows these motors to be used in the more hazardous Group A and B environments.

The purging process involves the use of a Pepperl+Fuchs “Type X” purging system, which can either be mounted directly on the motor or within 5 feet of it. This system uses a supply of compressed instrument air or inert gas to purge the motor enclosure, removing any flammable vapors or gases and preventing their accumulation. By maintaining a positive pressure inside the motor enclosure, the system ensures that hazardous substances cannot enter, thereby reducing the risk of ignition.

Why You Need Purged Motors

In environments classified as Class I, Division 1, the risk of encountering explosive gases or vapors is high, and any spark or high temperature within a motor could lead to a catastrophic event. Standard motors are not designed to handle such conditions, which is why purged motors are essential. The Pepperl+Fuchs “Type X” purging system is engineered to perform multiple air exchanges and maintain a consistent pressure of 0.25 inches inside the motor enclosure, ensuring that the environment within the motor remains safe even in the most hazardous conditions.

Additionally, the system includes an Electrical Power Control Unit (EPCU) that monitors the purging process and controls the motor’s power. The EPCU ensures that the motor only receives power once all safety criteria are met, and it will automatically shut down the motor if the safe pressure is lost. This layered safety approach significantly reduces the Hazardous (Classified) Area Rating within the motor and terminal box, in compliance with NEC – NFPA 70, Article 500, NFPA 496, and ISA 12.4 standards.

Applications and Certification

Purged motors are indispensable in industries where safety is paramount, such as chemical processing, oil and gas, and other sectors where explosive atmospheres are a constant threat. The Pepperl+Fuchs Type X purging system, which is certified for Class I, Groups A, B, C, D, and Class II, Groups E, F, G, Division 1, meets all necessary safety standards, including ATEX, NFPA 496, and IEC Ex.

While U.L. and CSA do not certify motors for Class I, Groups A and B, Division 1 locations, purged motors offer a viable solution by reducing the internal classification from a hazardous area to a non-hazardous one. This allows general-purpose equipment to operate safely within the protected enclosure.

ATEX & IECEx Classifications

Zone 1 Motors

Zone 1 Motors are designed for environments where hazardous substances, such as flammable gases, vapors, or mists, are likely to be present during normal operations. Classified under both ATEX and IECEx standards, Zone 1 is a designation that indicates a higher risk area where the potential for an explosive atmosphere exists regularly or intermittently. Motors used in Zone 1 must be constructed to prevent ignition and withstand the rigors of operating in these volatile environments. They are typically built with enhanced safety features, such as flameproof enclosures or pressurization systems, to ensure that any sparks, hot surfaces, or electrical arcs are contained, reducing the risk of ignition. These motors are essential in industries like oil and gas, chemical processing, and any other sectors where hazardous atmospheres are a regular part of the working environment.

Zone 2 Motors

Zone 2 Motors are designed for environments where hazardous substances, such as flammable gases, vapors, or mists, are not typically present during normal operations but could appear under abnormal conditions, such as in the event of a leak or equipment failure. Classified under both ATEX and IECEx standards, Zone 2 indicates a lower risk area compared to Zone 1, where the presence of an explosive atmosphere is infrequent and short-lived. Motors used in Zone 2 must be capable of operating safely without igniting any hazardous substances that might briefly be present. These motors often feature non-sparking components, increased safety designs, or other protective measures that minimize the risk of ignition. They are commonly used in industries like petrochemicals, pharmaceuticals, and manufacturing, where the likelihood of encountering a hazardous atmosphere is low, but safety cannot be compromised.

Dietz Electric’s Hazardous Location Motor Options

Dietz Electric offers a range of hazardous location motor options designed to operate safely in environments where explosive or flammable materials are present. These motors are engineered to meet the strict standards and regulations governing hazardous locations, including those defined by the National Electric Code (NEC) and the International Electrotechnical Commission (IEC). With a focus on reliability, durability, and safety, Dietz Electric’s hazardous location motors provide the performance and protection required for industries such as oil and gas, chemical processing, and mining, where the risk of explosion or fire is high.

NEMA UL – CSA Motors

UL Listed and CSA Certified Division 1 Explosion Proof Motors

Available Brands and Services

At Dietz Electric Co., we provide solutions for supplying and servicing Class I, Division 1 motors, focusing on Groups C and D. All of our motors have been tested and designed to meet or exceed NEMA and NEC specifications. They are also CSA- and UL-approved for utilization in explosive and hazardous locations.

Some of the explosion-proof motors that we currently supply include the following:

- ABB XP100

- Brook Crompton NEMA Explosion-Proof Motors

- Hyundai Explosion Proof Motors

- Worldwide Electric Corp. Explosion-Proof Motors.

- TECO EXP NEMA Premium Efficiency Explosion-Proof Motors

- Tatung Explosion-Proof NEMA Premium Efficiency Series

- Baldor Explosion-Proof Motors

- Leeson Rigid Base Explosion-Proof Motors

Aside from our catalog of explosion-proof motors, we offer a specialized selection of custom electric motors. These are tailored for operation in Division 1, Class A or B hydrogen-rich, or equivalent hazardous environments. They are available in all NEMA frame sizes, ranging from ¼ to 100 horsepower, and provide flexibility with foot and flange mountings.

We also provide repair and maintenance services for explosion-proof and custom electric motors. These include explosion-proof Class I, Division 1 motors (Class C and D) and Division 1, Class 2, E, F, and G motors.

Our qualified technical staff has the necessary expertise in electrical and mechanical aspects to ensure that all repairs adhere to various requirements. Examples include NEMA and the Institute of Electrical and Electronic Engineers (IEEE) Standard 112A.

Available Motors

ABB XP100 – Class I, Group C & D, Class II, Groups F & G, Division 1 Premium Efficiency

Here are the available motors and some of their respective features:

Features

- 1 to 300 HP

- Service factor, 40oC ambient

- T3C temperature code

- 900, 1200, 1800, or 3600 RPM

- 3 phase, 60 Hz; 230/460-volt operation under 25 HP, 460 volt 25HP and above; 200 & 575 volts available

- Class F insulation, Class B temperature rise

Brook Crompton UL/CSA Approved Class I Group C & D Class II Groups E, F & G T3B 140 – 250T frame UL/CSA Approved Class I Group D Class II Groups E, F & G T3B 280T and above

Features

- NEMA MG1 Part 31 Inverter Duty

- UL-certified 5:1 constant torque

- CSA-certified 10:1 constant torque

- SF 1.15 sine Wave. 1.0 SF SF VFD

- IP55 degree of protection

- NEMA Design B performance

- Class F insulation

Hyundai Explosion Proof Motors – Rigid Base

Features

- 1 to 250 HP

- 3600, 1800, and 1200 RPM

- 208-230/460 volt (1-125 HP)

- 460 volt (150-250 HP)

- TEFC enclosure

- 15 service factor

- Class F insulation

Worldwide Explosion-Proof Motors, Premium Efficient Class I, Division 1, Groups C & D, T3C Temp Code Class II, Division 1, Groups E, F & G (254T-449T only)

Features

- 1 to 300 HP

- 3600, 1800, and 1200 RPM

- 208-230/460 volt (1-100 HP)

- 460 volt (125-300 HP)

- TEXP enclosure

- 15 service factor

- Class F insulation

TECO NEMA Premium Efficiency Explosion-Proof Totally Enclosed Fan Cooled 1 HP through 150 HP Speed 3600, 1800, 1200 RPM Voltage 230/460V (usable on 208V), 575V Frequency 60 Hz

Features

- Inverter duty magnet wire

- Rugged cast-iron construction

- Non-sparking external fan

- Non-sparking brass flingers on both ends

- Oversized cast-iron conduit box

- Non-hygroscopic insulation system

- Zn-Cd plated hardware

Leeson Motors

Features

- 33 to 350 HP

- 1200, 1800, & 3600RPM

- 56 – 449T Frames

- 1 Phase up to 5 HP

- 115/230V, 230/460V

- Nema Premium Efficient

- UL and CSA Certified

CSA and Non Agency or Self Certified Hazardous Location Motors

Below are the types of specialized motors we provide, each meticulously crafted to meet the unique demands of diverse applications:

Class 1, Groups A, B, C, D, Division 2 Hazardous Location Motors

Dietz Electrical offers motors that fall into the Class 1, Groups A, B, C, D, Division 2 locations. These motors are tailored to handle distinct flammable substances such as acetylene, hydrogen, ethylene, and various other gases or vapors.

We carry products from leading manufacturers in the industry — including Elektrim, Brook Crompton, Siemens, TECO Westinghouse, and Hyundai — to guarantee strict compliance with NEC guidelines. This provides access to a diverse and high-quality selection of motors designed for use in concerning environments, ensuring that your operations remain safe and secure.

In-House Division 2 Hazardous Location Motors

Dietz Electric offers in-house produced Division 2 motors specifically tailored to meet the unique demands of hazardous environments. This non-agency-certified single-phase device features explosion-proof construction, prioritizing safety in potentially volatile settings. The traditional centrifugal switch is replaced with an intrinsically safe Sinpac solid-state switch. Meanwhile, the starting and running capacitors are integrated internally within the motor, enhancing performance efficiency and reliability.

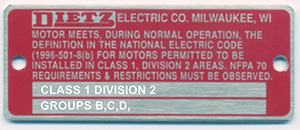

What sets our in-house Division 2 motors apart is their design for cooler operation. We opted for a larger frame size or a higher rating, ensuring optimal performance and increased safety margins. Strictly adhering to Division 2 recommendations and best practices, these motors are engineered to meet the highest safety standards. Each motor features Dietz nameplates, displaying a Class 1, Division 2, Groups B, C, and D rating. This verifies their compatibility for use in environments with flammable substances.

Dietz Electric: A Trusted Supplier of Premium Hazardous Location Motors for Critical Operations

If you are looking for a trusted supplier and manufacturer of specialized electric motors, look no further than Dietz Electrical! As a broad-line stocking distributor, we maintain a substantial inventory, ensuring swift access to the products you need. Beyond distribution, we also have the expertise to repair all the products we offer.

Class I, Division 2 Motors For Sale From Dietz Electric

Three-Phase Motors

Increasingly customer specification call for motors suitable for operation in Class 1, Division II hazardous locations. Dietz can supply motors that are Class 1, Groups A, B, C, D, Division II. We represent several manufactures that Supply various levels of division II protection. These include Elektrim, Brook Crompton, Siemens, TECO Westinghouse, Hyundai and Techtop. These motors are CSA certified for operation in Division II areas

For increased levels of safety and temperature requirement as low as T5 we make our own brand of Division II electric motors. These motors meets, during normal operation, The Definition in the National Electric Code (1996-501-8(b)) for motors permitted to be installed in Class 1, Division II areas. NFPA 70 requirements and restrictions must be observed. Advise ignition temperature of the potential hazard or “T” code and class with requests. Division 2 motors are Non (Agency) certified. If thermostats are installed they must be connected.

Single-Phase Motors

Currently there are no manufacturers that make or certify Division II single phase motors.

Dietz can produce non-agency certified Division 2 single phase motors. These motors are explosion proof construction. The centrifugal switch is replaced with an intrinsically safe Sinpac solid state switch, starting and running capacitors are internal to the motor. These motors are also one frame size larger, or one rating larger in order to produce a cooler running motor. All Division 2 recommendations, and practices are observed. These motors will have Dietz nameplates rated for Class 1 Division 2, Groups B, C, D.

These motors are available:

- 0.25 – 5HP

- 1200, 1800, 3600RPM

- 1.0SF

- 115/230VAC

- Sinpac Solid State Switch

- Internal Capacitors

- T2C – T4 Temperature Code

- Klixon Thermal protection available as an option

- 50 or 60HZ available

- Three Year Warranty

- Explosion Proof Terminal Box

ATEX & IECEx Motors

Zone 1 Motors - Hazardous Location Motors

ATB Flameproof Motors

ATB NORDENHAM GmbH has decades of experience. In 1952, the first explosion-proof motors in a flameproof enclosure were manufactured under the company name “Felten & Guilleaume” (F&G) at the Nordenham plant. Always aware of the market‘s needs, the company started developing and designing efficient, low-noise and low-maintenance machines early on which continue to earn the respect of the professional world today.

In 2002, “F&G Antriebstechnik” was successfully integrated in the ATB Group. Today, ATB NORDENHAM GmbH is one of the industry‘s leading suppliers. The companys specialization in motors in a flameproof enclosure means that customers benefit from its comprehensive expertise, long-standing experience and outstanding professional competence. ATB is also a competent partner when it comes to special products such as motors with an integrated frequency inverter in a flameproof enclosure and offshore motors or water-cooled configurations. The custom design, safety and reliability of all our solutions meet the specific requirements of our customers and legal requirements.

Brook Crompton Motors

EExd Explosion Proof Hazardous Location Motors

- Motors comply with CENELEC/EURONORM Standards EN60079 Certified by BASEEFA / ATEX

- Zone 1, Groups IIA & IIB, IIC Special Order

- Totally Enclosed Fan Cooled Enclosure

- All motors suitable for T4 application

- Cast Iron Construction

- Class F insulation

- Dual rated 380-415 – 440-480V 50/60HZ

- Service Factor 1.0 50Hz

- C & D Flanges available

- F2 to F1 convertible up to 180 frame. 200 and above are F0, F2, F1 convertible

- Warranty: 3 years

ABB Motors

Low voltage flameproof motors for hazardous locations

| Type of protection | Ex d / Ex de |

| Output Power | 0.55 to 950 kW |

| Frame Size | IEC 80 to 450 |

| Number of Poles | 2 to 8 |

| Voltages | All commonly used voltages |

| Frequency | 50 or 60 Hz |

| Protection | IP 55 |

| Protection Type | For zone 1 or 2 Temperature classes T1 – T4 |

| Certificates | IECEx / ATEX certified, Equipment protection levels (EPLs), GOST (Russia), CQST (China), Inmetro (Brazil) |

| Features | = VSD applicable as standard = Variants for different standards in the oil and gas sector, such as Norsok and Shell, as well as for VIK = Marine use and open deck with most classification societies |

High voltage flameproof motors

Flameproof motors certified according to EN standards, fulfilling ATEX Directive 95/9/EC, CSA-UL, GOST (Russian)

Features

Motors are designed to withstand without any damage the pressure caused by an internal explosion and are also able to prevent flame propagation outside

Advantages

No purging before starting No pressurization system required No inert gas needed No thermal limitation for “te” time No need for system test in VSD applications Individual certification not required Low maintenance costs

Totally enclosed, fan cooled high voltage motors, type of protection Ex d IIB/IIC, Ex de IIB/IIC

| Output Power | 160 to 8000 kW |

| Frame Size | IEC 355 to 900 |

| Number of Poles | 2 to 18 |

| Voltages | LV – 11 kV |

| Frequency | 50 or 60 Hz |

| Environment | IP 55 as standard (higher on request) |

| Protection | For zone 1 or 2 Temperature classes T4 |

| Mounting | Horizontal or Vertical |

| Cooling | IC411 or IC511 |

| Bearings | Antifriction or sleeve |

| Supply | Direct-on-line or variable speed drive |

| Standards | EN, IEC, BS, ANSI, NEMA, IEEE, VDE, CSA, UL, GOST |

Zone 2 Motors - Hazardous Location Motors

The environments are classified as Zone 2, groups IIA, IIB and IIC, and as Zone 22, groups IIA, IIB and IIC. The most common gases included in this classification are: acetone, ammonia, benzene, butane, butanol, buthylic alcohol, ethane, ethanol, acetate of ethyl, gasoline, heptanes, hexanes, natural gas, methanol, oil naphtha, propane, propanol, toluene, esthyrene, solvents in general, acetaldehyde, cyclopropane, diethylic ether, ethane, monoxide of carbon, acetylene, butadiene, oxide of ethane, hydrogen, oxide of propylene and gases containing over 30% of hydrogen.

EEx nA Zone 2

- Motors comply with CENELEC/EURONORM Standards EN60079 Certified by BASEEFA / ATEX

- Zone 2, Group II T3 non sparking

- Totally Enclosed Fan Cooled Enclosure

- Cast Iron Construction

- Class F insulation

- C & D Flanges available

- F2 to F1, F3 convertible

- Warranty: 3 years

EEx nA Zone 2

- Motors comply IECEX/ATEX

- Ex nA II T3 Non- Sparking

- Totally Enclosed Fan Cooled Enclosure

- IP55 Protection

- Class F insulation

- Class B Temperature Limits

- 50HZ

- 230/400/415V, 400/415/690V

- IEC Frame sizes

- Warranty: 3 years

Applications of Hazardous Location Motors

Hazardous location motors are critical components in industries where safety is paramount due to the presence of explosive or flammable substances. These specialized motors are designed to operate safely in environments where gases, vapors, dusts, or fibers pose a significant risk of ignition. From oil refineries and chemical processing plants to grain silos and textile mills, hazardous location motors are indispensable in ensuring that operations run smoothly and safely in these high-risk areas.

Petroleum Refining Plants

The production and processing of crude oil in petroleum refining plants involves handling highly volatile and combustible chemicals. Class I, Division 1 motors are essential in these settings for powering machinery such as pumps and compressors.

Utility Gas Plants

Utility gas plants deal with the processing and distribution of natural gas, which can be combustible. The motors power various equipment in these facilities, ensuring that they operate safely in environments with explosive materials.

Spray Painting Areas

Environments where spray painting occurs often have high concentrations of volatile solvents and paint fumes. Class I, Division 1 motors are used to power equipment like exhaust fans and ventilation systems in these areas.

Aircraft Hangars

Aircraft hangars contain aircraft, fuel, and other flammable materials, creating a potentially hazardous environment. The motors are employed to power equipment such as ventilation systems and fuel transfer pumps. Their ability to contain internal explosions and limit the risk of external ignition contributes to the smooth operation of activities within the hangar.

Oil and Gas Exploration Sites

In oil and gas exploration sites, where the extraction of hydrocarbons occurs, the motors operate essential equipment such as drilling rigs and pumps. These components are designed to work in environments with combustible gases.

Mines

Mines often contain explosive gas and dust atmospheres, posing particular dangers. Class I, Division 1 motors are used in various mining equipment, providing a dependable power source while reducing the fire risk. In addition, their sturdy construction and safety features help to improve the overall safety and efficiency of mining operations.

Certifications and Compliance

Government or independent approval agencies certify electrical equipment intended for use in various hazardous locations. In North America, three of the principal agencies are:

Recognized UL Component Mark for Canada and the US

Underwriters Laboratories (UL) provides certification, evaluation, and testing services. They certify products based on their adherence to both ordinary location safety measures and hazardous area protection methods. UL also requires compliance with ANSI and CAN standards.

Every division marking has an area classification under the Class/Division/Group system and includes the product’s temperature class. UL certified products are marked as UL listed or UL classified.

Canadian Standard Association – CSA Certification

Canadian Standard Association (CSA) provides testing, inspection, and certification services. The organization employs either the Class/Division/Group system or the Zone system when marking certified equipment and products. CSA marks may also include the temperature class, protection concept code, and gas group as needed.

Factory Mutual (FM)

Factory Mutual (FM) has a global certification program. In addition to certifying equipment for use in hazardous locations, the agency tests and evaluates building materials, roofing and wall assemblies, and construction, electrical, and fire-related detection equipment.

“FM Approved” certifications mark the specific model of approved equipment and the FM approval class.

ATEX & IECEx Certifications

ATEX and IECEx are two of the most important certification systems for equipment used in potentially explosive atmospheres. ATEX (Atmosphères Explosibles) is the European Union directive that regulates the manufacture and use of equipment in hazardous areas. It categorizes equipment based on the level of protection required and the type of explosive atmosphere present. ATEX certification ensures that products meet essential health and safety requirements and are suitable for use in potentially explosive environments within the EU.

IECEx, on the other hand, is an international certification system created by the International Electrotechnical Commission (IEC). It aims to standardize the testing and certification of equipment used in explosive atmospheres worldwide. IECEx certification involves rigorous testing to international standards and provides a single, globally recognized proof of compliance. This certification is particularly valuable for manufacturers looking to market their products internationally.

While ATEX and IECEx have some differences in their approach and geographical applicability, they share many similarities in their core standards and testing requirements. Both systems classify hazardous areas into zones based on the frequency and duration of the occurrence of an explosive atmosphere. They also require thorough documentation, quality management systems, and ongoing compliance measures.